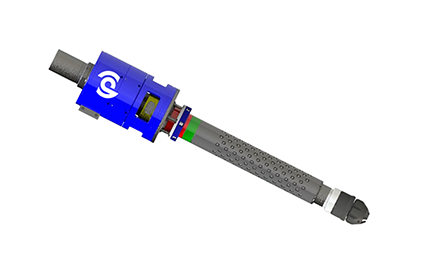

Through technology and competency programs, we can deliver POB reductions across multiple phases of the program. Linked with our Torq-Tek Torque Monitoring Systems, we can enable the remote observation of connection make-up in real time in our Real Time Operating Center (RTOC) in Houston, Parker Wellbore Satellite Locations.

Connection make-up can be monitored from anywhere in the world, no longer requiring thread connection specialists to be at the wellsite but still providing the ability to observe connection make-up and approve, as necessary.

Through our Virtual Global Support (VGS™) systems including intrinsically safe mixed reality headsets, RealWear, the thread specialists can perform visual thread inspections with the support of our trained technicians, further reducing POB and associated costs with 3rd party specialty services

Benefits of Remote Connection Observation and Monitoring

- Enables torque turn monitoring services to be performed remotely from RTOC or other satellite locations, reducing POB at the well site.

- Cost reductions in personnel mobilization to and from the well site.

- Provides real-time access of connection monitoring to thread manufacturers for evaluation and oversight without having to be at the wellsite, improving connection integrity.

- Carbon emission reductions with less personnel transportation to and from location required.

- Removes the requirement for wellsite 3rd party connection representatives, which can be office based.

- Cloud-based storage systems for end-of-well reports, and client access.

- Full recording of the job as well as the end of well graphical report