Company Description

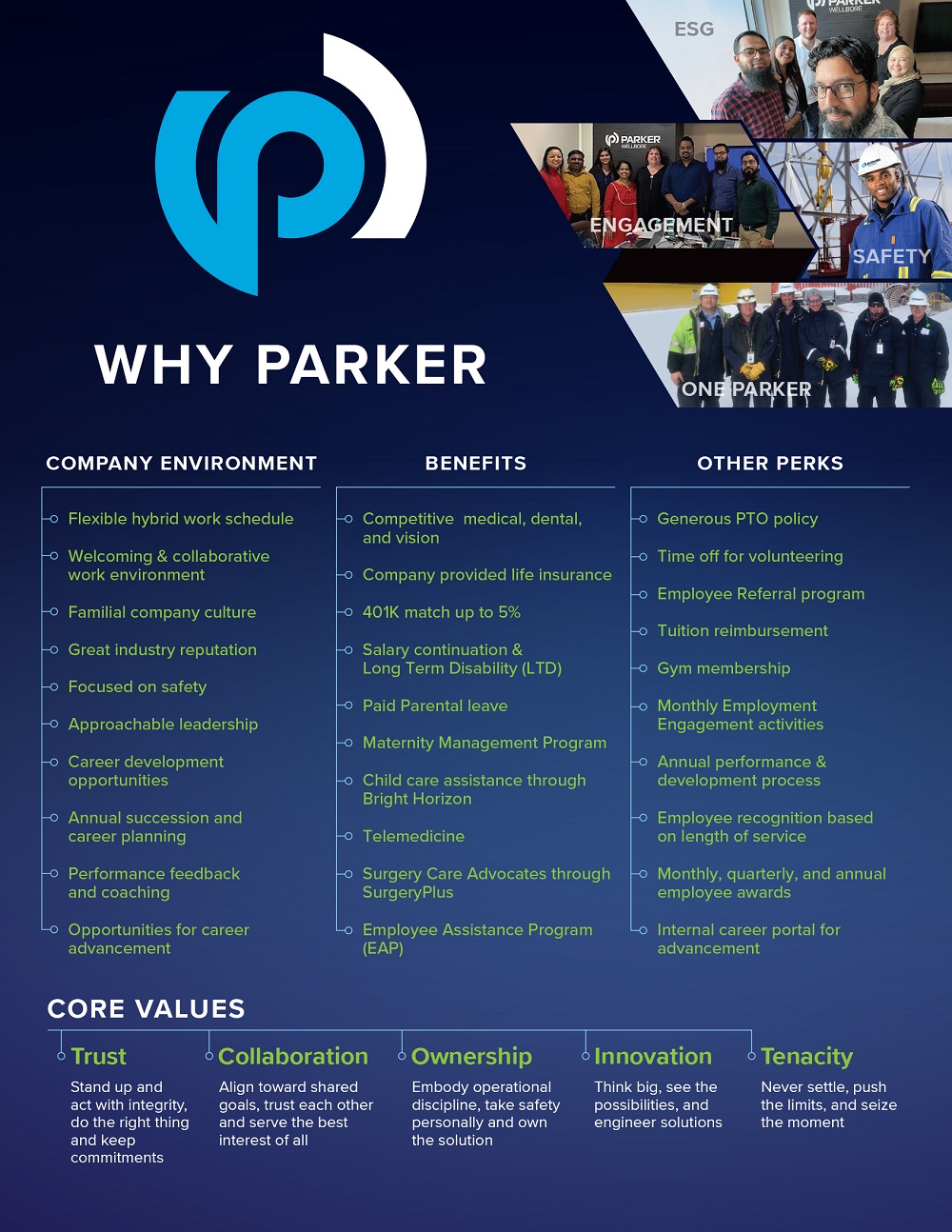

At Parker Wellbore, we pride ourselves on providing safe, efficient, and reliable drilling operations on a global basis. Founded in 1934, our employees have helped us grow to become a leader in the drilling industry through creativity, innovation, expertise, and environmental social governance. We are well grounded by our values of trust, collaboration, ownership, innovation, and tenacity, which position us to deliver the highest quality results for our customers. We believe that it is not only what we do, but how we do it, that sets us apart from the rest.

Learn more about Parker Wellbore by visiting our website at www.parkerwellbore.com

Job Description

This position is responsible for wide range of welding jobs such as Carbide Dressing, Hard Banding, Hard facing, Saw welding and general fabrication works.

Responsibilities

o Perform all work safely and in accordance with the Company's HSE policies and procedures.

- Set-up/run RT & UT Quality Vessel Weld Processes – 3 (GMAW, FCAW, GTAW).

- Set-up/run RT Quality Pipe Weld – All Positions (6G).

- Set-up/run UT Quality Nozzle Welds – All positions (6G).

- Set-up/run Carbon Arc Gouging.

- Able to make any UT or RT Weld Repair.

- Clean and stamp all welds.

- Set-up/run all structural non-code welds.

- Know how to run all welding equipment.

- Ability to read drawings, WPS’s/PQR’s. - Ability to lead others and plan ahead – Good.

- Knowledge of PT, MT, UT, RT methods.

- Ability to make correct decisions – Good.

- Speed of accomplishing tasks – Fast. - Ability to work safely – Best.

- Average Percent of weld repairs - <0.5%.

Additional functions

This position is based at Yard at Barmer

Qualifications

Qualifications

- A High School diploma is required.

- Should have at least 6 years of specific work experience.

- Must possess necessary licenses, certificates and registrations to safely perform the functions of a welder.

- Must be able to operate hand and power tools specific to welding.

- Must be a detail oriented, self-starter and able to work with little supervision while maintaining goals/tasks.

- Must have good written and verbal communication skills and be able to effectively communicate with staff, management, customers and vendors.

- Must possess sound reasoning skills and have the ability to follow directions.

Working Conditions

The demands of each position may vary by region and/or function. All demands must be met in order to perform the essential functions of the job. Essential functions are routinely performed on the job and removal of these functions would fundamentally change the position. Based on the region or job function, demands include but are not limited to the following:

FIELD

- Ability to work in adverse weather conditions

- Ability to work in remote, isolated environments

- Ability to work in hazardous and noisy conditions

- Ability to work in enclosed spaces

- Ability to operate motor vehicles and/or heavy equipment and/or power tools

- Ability to work at heights

- Wear Personal Protective Equipment as required

- Frequent standing, walking, stooping or kneeling

- Must be able to lift, carry and move objects up to 50 pounds

- Ability to work in a team environment taking into consideration alternative and diverse perspectives

- Ability to comprehend, remember and follow directions and comply with all company policies, procedures and standards

OFFICE

- Frequent standing, walking, stooping or kneeling

- Use of repetitive wrist and hand movements at a computer

- Sit/stand while performing sedentary work

- Ability to work in a team environment taking into consideration alternative and diverse perspectives

- Ability to comprehend, remember and follow directions and comply with all company policies, procedures and standards