Delivering Well Integrity

Our approach to well construction services begins with understanding your challenges across the entire drilling and completion program. Starting with pre planning operations, our global teams collaborate with you to tailor cost effective solutions without compromising safety and service quality.

Tubular Running Services

Parker Wellbore’s Tubular Running Services, provides technologies and services, with a focus on the total tubular cycle from the pipe mill to the wellsite.

Our Offline Operations

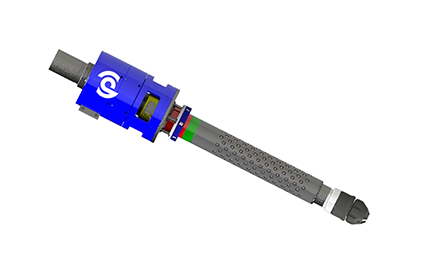

Drilling while Casing (DwC)

The application of drilling while casing, when compared to conventional drilling, can deliver time savings of up to 50%. Our Dril-Tek CRT System with enhanced capabilities in delivering higher RPM for longer periods, meet the rigors of Drilling while Casing operations in well construction.

Supported by software technologies in drillability evaluation and torque and drag modeling, and strategic partnerships in Drilling while Casing bits and accessories, our systems can be deployed and supported globally or through our Real Time Operating Center, ensuring oversight on drilling KPI’s in real time.

Mechanical Cementing Products and Casing Accessories

Drilling Tools and Services

iTS Energie Drilling Jar and Energizer

Quality Wellbore Focus

Conventional TRS Services

With decades of experience, our specialized technical support and wellsite operations teams provide the right services that deliver connection integrity safely and efficiently.

Our extensive range of casing and completion tongs, packaged with our proprietary torque monitoring systems and software ensure that tubulars are made up correctly to the pipe manufactures recommendations, minimizing thread and tubular damage. Handling tools such as casing elevators and slips from 2 3/8 to 36” along with flush mounted casing and completion spiders provide a hands-free solution to heavy rig floor activities, reducing risk and non-productive time (NPT).

Casing Running Tools (CRT)

With its patented gripping system and integrated safety interlock systems and link tilt bails, the Top-Tek Casing Running Tool (CRT) family provides a multi-task approach to casing running systems. CRT tools incorporate the functions of both casing make-up, fill-up, and circulation as well as the ability to rotate and reciprocate the casing string to bottom, reaming through troublesome wellbores.

- Top Tek M2 System. 500t 4 ½” to 24”, torque capacity 80,000ftls with up to 60 RPM

- Dril-Tek Casing while Drilling System, 500t 4 ½” to 24” torque capacity 100,000ftlbs up to 150 RPM for drilling and reaming operations

- SC Super Compact Tool, 350t 4 1/”2 to 13 3/8 torque capacity up to 50,000 Ftlbs , integrated wireless torque sub

- Sub Tek Wireless Torque Sub ratings EXII1G, Ex1AT4Ga, CSA/UL/ATEX/iECEx for communication to our Torq-Tek Torque Monitoring Systems for connection make up and evaluation

Tubular Management Services

Our multi-skilled crews in tubular management and running services are qualified to ensure tubular storage, preparation, transportation, handling, and connection make-up are performed in accordance with quality plans and programs, ensuring connection integrity and extended life of production. Our offline operations and services deliver a unique approach to time saving by utilizing offline backing systems and catwalks, reducing connection time at the rotary table.

Remote Connection Monitoring

Through technology and competency programs, we can deliver POB reductions across multiple phases of the program. Linked with our Torq-Tek Torque Monitoring Systems, we can enable the remote observation of connection make-up in real time in our Real Time Operating Center (RTOC) in Houston, Parker Wellbore Satellite Locations.

Connection make-up can be monitored from anywhere in the world, no longer requiring thread connection specialists to be at the wellsite but still providing the ability to observe connection make-up and approve, as necessary.

Through our Virtual Global Support (VGS™) systems including intrinsically safe mixed reality headsets, RealWear, the thread specialists can perform visual thread inspections with the support of our trained technicians, further reducing POB and associated costs with 3rd party specialty services

Benefits of Remote Connection Observation and Monitoring

- Enables torque turn monitoring services to be performed remotely from RTOC or other satellite locations, reducing POB at the well site.

- Cost reductions in personnel mobilization to and from the well site.

- Provides real-time access of connection monitoring to thread manufacturers for evaluation and oversight without having to be at the wellsite, improving connection integrity.

- Carbon emission reductions with less personnel transportation to and from location required.

- Removes the requirement for wellsite 3rd party connection representatives, which can be office based.

- Cloud-based storage systems for end-of-well reports, and client access.

- Full recording of the job as well as the end of well graphical report

iTRS (Integrated Tubular Running Services)

Parker’s TRS Services are also provided through our global drilling rig operations. Whether they’re on Parker Wellbore rigs or rigs under our Operations and Management program, Parker iTRS results in a reduction of 3rd party services along with gains in efficiency. This coordination in rig operations means shorter casing running times on your well.

Our multi-skilled rig crews, with specialty TRS technicians, provide the full suite of casing and completion running operations, ensuring operations are planned in accordance with real time drilling operations.

Benefits of iTRS Services

- Expertise in tubular readiness for premium threaded connections ensures each joint is prepped to the connection manufacturer’s compliance and running lists are incorporated into the rig operations.

- Online or offline, Parker Wellbore incorporates rig technologies to ensure both standard and CRA tubulars are delivered safely and efficiently to the rotary table.

- Our multi-skilled crews and TRS specialists work together to optimize run times in casing programs and in coordination with drill floor operations for both CRT and power tong services.

- The Tork-Tek Monitoring Systems ensure each connection is made-up and evaluated to the connection manufacturer’s parameters, building well integrity.

- Software generated reports provide an overview of connection performance and traceability and built into our end of well reports.

- Reduction in 3rd party service company personnel, reducing millage driven and carbon emission reduction with less personnel traveling to location

To learn more about what Parker Wellbore can do to help you meet your well construction needs, please contact us at:

United States and Canada: NAMsales@parkerwellbore.com or (281) 406-2000

International | Parker Wellbore : salesinfo@parkerwellbore.com or +1 281-406-2000

BHA Drilling Tools

We offer a complete range of BHA drilling solutions to the energy industry, with optimized tool placement and BHA design to help make your operation a success. Our API Q1 certified manufacturing and service facilities are strategically located around the world to support you and help increase the efficiency of your operation.

Our proprietary jars and accelerators – manufactured in-house by our experienced personnel – have been used extensively across the Middle East, Asia, and Latin America since 2008; and continue to provide reliable results across our operations. You can trust that we are on hand to provide you with a complete suite of premium products to meet your needs; either manufactured in-house or procured through our wide network of well-reputed global suppliers.

- Shock Tools

- Jars

- Accelerators

- Stabilizers

- Friction Reduction Tools

- Under-reamers

- Mud Motors

- Micro-reaming Tools or Active Stabilizers

To learn more about what Parker Wellbore can do to help you meet your well construction needs, please contact us at:

International | Parker Wellbore salesinfo@parkerwellbore.com or +1 281-406-2000

CASE STUDIES

Parker’s CRT Operations Achieve KSA Milestone for Operator

Middle East Milestone – 9,000,000, 5 years

Continual improvement saves $24m in 2 years

PRODUCTS SHEETS

Tubular Running Services – 15% Offshore

Top TeK SC Tool

TORQ-TEK Z11